Table of Contents

ToggleSectoral Impacts of Fully Automated Packaging Machines

Across numerous industries—ranging from food and beverage to pharmaceuticals, cosmetics, and beyond—automated packaging solutions have become increasingly vital. The modern business landscape demands higher productivity, reduced costs, and impeccable quality control. In this environment, Sectoral Impacts of Packaging Machines have been seen in everything from boosted production speeds to enhanced safety measures for products and workers alike. Companies that fail to embrace these advanced packaging methods often find themselves lagging behind in a highly competitive market.

What is Fully Automated Packaging Machines and How Does It Work?

Fully automated packaging involves the use of advanced mechanical and electronic systems to handle every phase of the packaging process with minimal human intervention. This process can start as early as product sorting, continue through package sealing, labeling, and quality checks, and finally conclude with palletizing or preparing goods for shipment. The goal is to create a streamlined flow that reduces errors, optimizes speed, and ensures consistency from one item to the next.

Many fully automated packaging systems rely on a combination of conveyor belts, robots or robotic arms, sensors, and programmable logic controllers (PLCs). For example, sensors can detect product orientation and size, relaying this information to a central controller that adjusts machine speed or packaging parameters in real time. In advanced setups, cameras equipped with machine vision systems can spot defects or orientation issues, halting the line or diverting certain items into designated bins for rework or disposal.

One of the key features of these systems is their versatility. Whether you need to handle delicate products like eggs or heavy items such as industrial components, a fully automated setup can be configured to manage unique packaging requirements. Changeover mechanisms allow operators to switch between different product lines quickly, reducing downtime and improving overall efficiency. This adaptability underscores the Industry Impacts of Packaging Machines, as businesses can handle growing product varieties with little to no compromise on speed or accuracy.

Sectoral Impacts of Packaging Machines: How Does It Increase Productivity?

The Industry Impacts of Packaging Machines become most visible in the context of productivity gains. Traditional manual packaging requires continuous labor, which can be time-consuming, prone to errors, and difficult to scale. By contrast, an automated line can run at a near-constant speed, only pausing for routine maintenance or brief adjustments. This consistency in operation directly translates into higher throughput.

Automation also excels at maintaining uniformity. Instead of relying on the dexterity and speed of human workers, the machine’s standardized programming ensures that each product is packaged identically. This consistency is a major advantage in industries where product look and feel are significant selling points—cosmetics, for instance, where any blemish on the packaging might affect customer perception.

Additionally, automated packaging allows for real-time tracking of performance metrics. Sensors and software dashboards provide insights into machine uptime, error rates, and product counts. Companies can analyze these metrics to identify and eliminate bottlenecks, predict maintenance needs, and continuously refine their processes. The net result is a packaging line that not only works faster but also smarter, delivering a boost to overall operational efficiency. This is critical for businesses aiming to expand their market share or quickly pivot when seasonal or unexpected demand surges arise.

Contribution of Automation to Cost and Time Management

When companies consider the Industry Impacts of Packaging Machinery, cost and time management often top the list of priorities. Automation can offer immense savings in both of these areas. Although the initial investment in machinery, software, and integration can be substantial, many businesses see a rapid return on investment due to reduced labor expenses, minimized product damage, and lower waste.

From a cost perspective, automating the packaging process can help eliminate repetitive manual tasks, thus reallocating human labor to more specialized roles that add greater value. Rather than having workers focus on mundane tasks like placing products in boxes, they can manage quality control oversight or handle complex equipment adjustments. This shift often leads to a more motivated workforce that can develop specialized skills to operate and maintain sophisticated equipment.

Time management is another major factor. Automated systems can operate 24/7 with minimal supervision, dramatically increasing throughput. Human fatigue, scheduling conflicts, and sick days become less of a factor. Moreover, advanced controls enable quick changeovers from one product to another, reducing downtime between production runs. When markets demand a fast turnaround, or when consumer preferences shift rapidly, such flexibility can be the difference between profit and loss. With optimized cost and time factors, companies can maintain or even expand profit margins without compromising on quality.

Automated Packaging Applications that Improve Production Quality

The next advantage to consider is quality—an aspect often overlooked until consumer complaints arise or product returns pile up. Automated packaging lines help maintain stringent quality standards. From ensuring that each package is sealed with exactly the right amount of adhesive to verifying that labels are perfectly aligned, these systems reduce human error and increase reliability.

In sectors such as pharmaceuticals or food processing, cleanliness and hygiene are paramount. An automated packaging line minimizes direct human contact with the products, thereby lowering the risk of contamination. Some lines incorporate vacuum or modified atmosphere packaging to preserve freshness, extending the shelf life of perishable goods. Meanwhile, vision systems can monitor fill levels or detect foreign objects, immediately alerting operators or stopping the line if issues arise.

Sectoral Impacts and Examples of Packaging Machines in Different Sectors

Although packaging technology finds most frequent mention in the context of fast-moving consumer goods (FMCG), the Industry Impacts of Packaging Machines stretch across a wide spectrum. Below are some notable examples:

Food & Beverage

Automated bottling, capping, and labeling systems can drastically reduce the risk of contamination. They also enhance throughput by ensuring that each product is filled and sealed consistently. This precision is vital for items like dairy products or carbonated beverages, where overfilling or underfilling can lead to substantial product loss or compromised quality.Pharmaceuticals

Here, packaging isn’t just about efficiency; it’s also about safety and compliance. Machines that carefully count pills or fill liquid medications into sterile containers help meet exact dosage requirements. Tamper-evident seals, child-resistant caps, and track-and-trace features are all supported by advanced automated lines.Cosmetics

In a market where presentation greatly impacts consumer choice, automated machines ensure consistent bottle labeling and exact fill volumes. Many systems can accommodate a variety of container shapes and sizes, providing essential flexibility for product lines that may offer multiple variants.Chemicals & Industrial Goods

Bulk items like paints, solvents, or cleaning agents require robust packaging to prevent spills or accidents. Automated machinery can fill large drums or intermediate bulk containers with minimal waste, reducing the risk of costly leaks or contamination.E-commerce & Retail

Automated packaging solutions, such as bagging systems or corrugated box assembly lines, help e-commerce companies meet large order volumes quickly. This is especially important during peak shopping seasons when orders can skyrocket.

Across all these sectors, packaging machines streamline workflows, reduce lead times, and help maintain compliance with industry regulations.

How to Gain Competitive Advantage with Packaging Machines?

In today’s global marketplace, speed and reliability are paramount, and this is where the Industry Impacts of Packaging Machinery offer a strategic edge. First and foremost, automated packaging can significantly reduce lead times. Customers receive products faster, improving satisfaction and fostering loyalty. For e-commerce or retail businesses, quicker dispatch can also reduce cart abandonment rates and boost sales conversions.

A second avenue for competitive advantage is branding and product differentiation. Automated systems guarantee pristine packaging, which can be key for premium goods or products where appearance influences buying decisions. From adding custom inserts to branding boxes with intricate designs, automation makes it feasible to produce high-quality packaging at scale. This consistent presentation builds trust and enhances perceived value.

What to Consider When Choosing Fully Automated Packaging Machines?

Choosing the right automated packaging solution requires thoughtful evaluation of technical, operational, and financial factors. Here are some key points:

Production Volume and Speed

Understanding your current and projected output levels is vital. If you foresee significant growth, it’s better to invest in a system that can be upgraded or scaled to meet future needs.Product Variety

If you deal with multiple product lines or various packaging formats, look for machines offering quick and easy changeovers. This ability to handle diverse packaging requirements can be a major asset when market demands shift.Maintenance and Support

Ongoing technical support is crucial. Ensure that spare parts are readily available and that the manufacturer or supplier provides training for your operators and technicians.Integration with Existing Systems

Your new packaging line should communicate seamlessly with upstream production equipment and downstream logistics software. Proper integration can unify data collection and streamline workflows.Total Cost of Ownership

Beyond initial purchase, consider installation costs, energy use, maintenance fees, and potential upgrades. Comparing these expenses to labor savings and increased production can clarify return on investment timelines.Compliance and Safety Features

In regulated industries like pharmaceuticals or food, compliance with standards like GMP (Good Manufacturing Practice) is essential. Make sure the equipment can meet all relevant regulatory requirements.

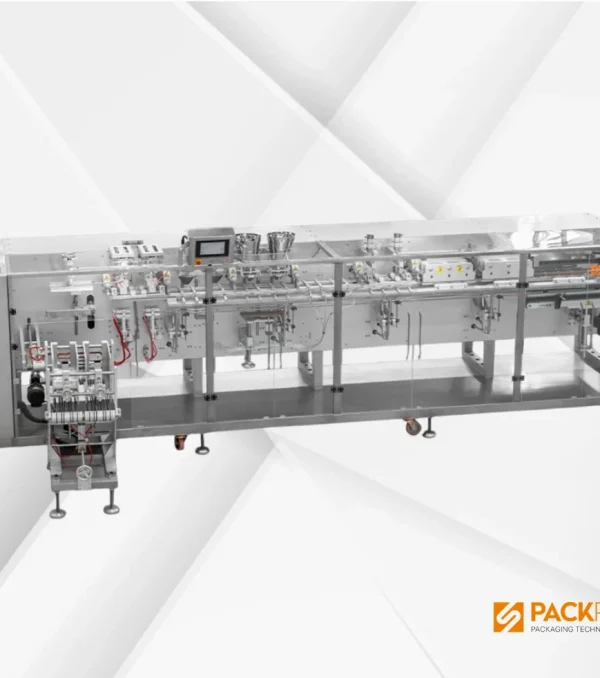

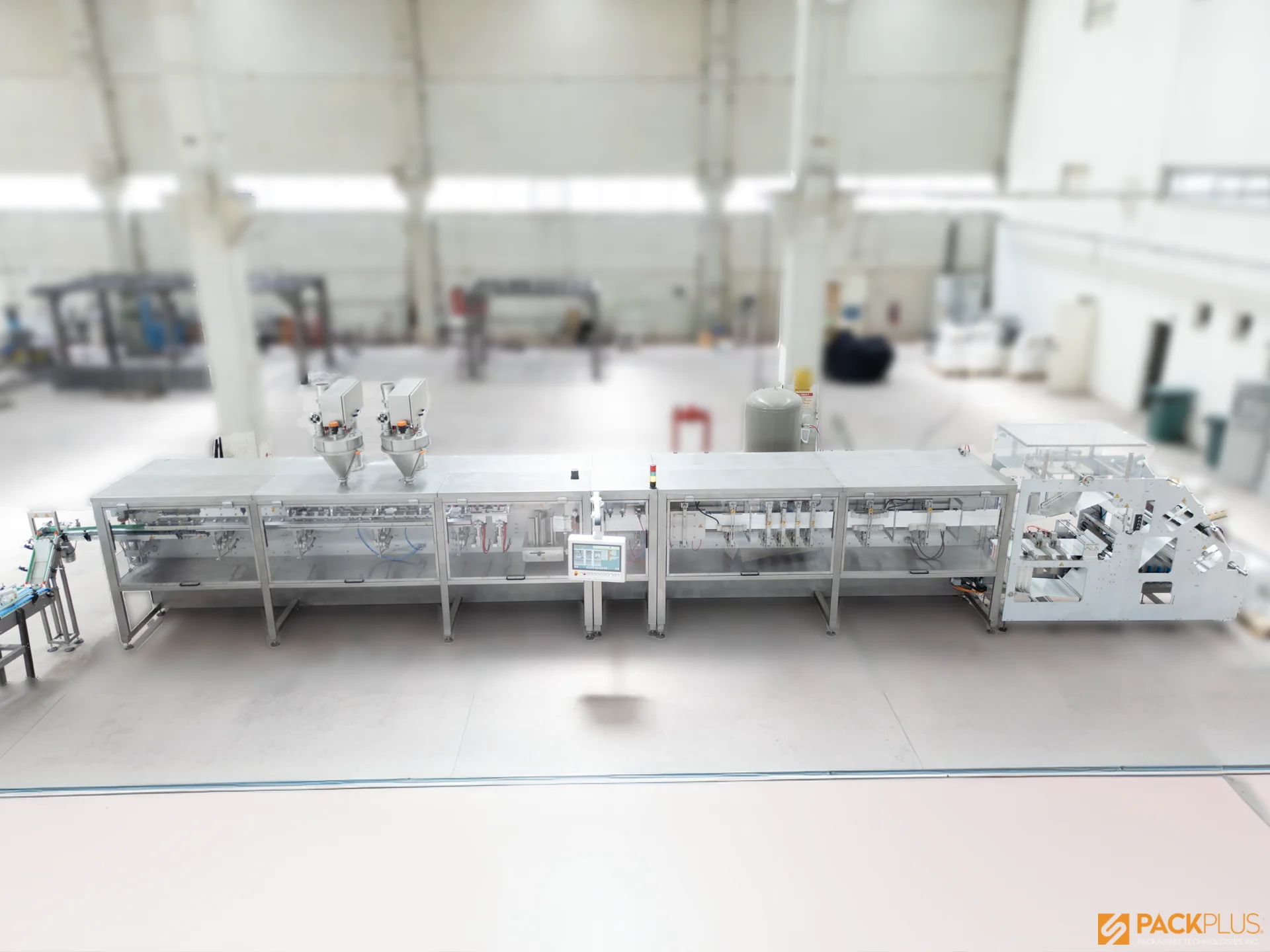

Below you can view the Packaging Machines solutions of Packplus.

Integration of Industry 4.0 and Packaging Technologies

Industry 4.0 signifies a shift toward interconnected, data-driven manufacturing, and packaging machinery is a critical component of this trend. Machines equipped with sensors send real-time performance data to centralized dashboards, allowing managers to make immediate adjustments to production speed, temperature settings, or labeling precision. This level of control dramatically reduces downtime and can optimize production cycles.

Big Data analytics are also shaping the Industry Impacts of Packaging Machines. By analyzing historical machine data, businesses can forecast maintenance, optimize inventory for packaging materials, and even predict demand fluctuations. Such predictive capabilities help companies remain agile, responding quickly to market changes while keeping internal processes efficient. Over time, this synergy between Industry 4.0 and packaging automation fosters a more sustainable, flexible, and customer-centric operation.

Conclusion

The Industry Impacts of Packaging Machines go far beyond the simple task of enclosing products in boxes or wrapping materials. From increasing output speed and ensuring consistent quality to integrating advanced data analytics and adhering to environmentally responsible practices, automated packaging systems are at the forefront of modern manufacturing and logistics. Selecting the right equipment for your business, however, requires a holistic approach—one that takes into account technical needs, compliance regulations, and the overarching market landscape.