Table of Contents

TogglePackaging Machine Prices 2025

In today’s manufacturing world, packaging isn’t just a finishing touch — it’s a key part of how a product is presented, preserved, and delivered to customers. Whether you’re producing snacks, coffee, cosmetics, or cleaning products, the packaging stage can make a big difference to efficiency, product quality, and brand perception. As we head through 2025, packaging machine prices can vary widely depending on the type of machine, the technology behind it, and the demands of your industry. This guide breaks down the main factors that influence cost, highlights the most in-demand models this year, and shows you where the best opportunities lie for a smart investment.

Key Factors Affecting Packaging Machine Prices

The price of a packaging machine comes down to more than just what you see on the spec sheet.

Production capacity is one of the biggest drivers. A machine capable of packing thousands of units an hour will naturally cost more than one designed for smaller-scale runs. Along with speed, precision is a big factor — especially for products where exact weight or volume is critical.

Technology level also plays a huge role. Machines with advanced automation, robotic handling, AI-powered quality control, and integrated weighing and sealing systems tend to sit at the higher end of the price spectrum. These upgrades can significantly reduce labor costs and waste, which often justifies the extra investment.

The build quality and materials matter, too. Stainless steel frames, food-safe finishes, and heavy-duty components can raise the price but also extend the machine’s working life and lower maintenance costs.

And finally, after-sales service is something too many buyers overlook. Solid technical support, fast access to spare parts, and comprehensive warranties may add to the upfront cost, but they protect your production line from costly downtime.

2025’te En Çok Tercih Edilen Paketleme Makinesi Modelleri ve Fiyatları

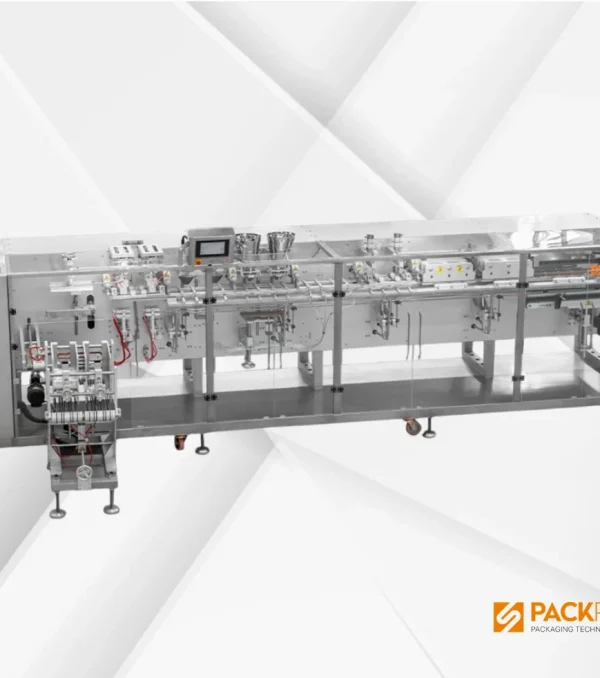

In 2025, doypack packaging machines are among the most prominent models in the packaging industry. Widely used across various sectors such as food, detergent, and pet food, these machines not only provide an attractive packaging appearance but also protect products from external factors. Thanks to their flexibility, they can handle packaging in different weights and designs, making them a preferred choice for many businesses.

For single-portion products like coffee, sugar, and spices, vertical packaging machines stand out. These machines offer high-speed and hygienic production, playing a significant role especially in the food and beverage industry.

Packaging Machine Price Ranges by Industry

Not all industries have the same requirements, and that’s reflected in the price of the machines they use.

In the food sector, hygiene and safety standards are strict. Machines must be easy to clean, built with food-grade materials, and designed to prevent contamination — all of which can raise costs.

For detergents and cleaning products, the machine’s ability to handle powders, liquids, or capsules with precise dosing systems is key. These features often require custom engineering.

The pharmaceutical and cosmetic industries demand unmatched precision, contamination control, and compliance with regulatory standards like GMP or FDA — resulting in more complex and costly equipment.

Pet food production often involves large, heavy packages and the need for robust sealing systems to maintain freshness, which can push machine designs toward heavier-duty, higher-capacity builds.

Best Value-for-Money Packaging Machine Options

A value-for-money packaging machine is not simply the cheapest option on the market — it’s the one that balances cost, performance, and longevity.

For smaller producers, semi-automatic machines can offer a big boost in speed and consistency without the investment required for full automation.

Larger manufacturers typically benefit from fully automatic systems that cut labor costs, minimize human error, and operate around the clock.

Beyond that, energy efficiency, ease of maintenance, and the flexibility to handle different product sizes or packaging formats can make a big difference in the total cost of ownership.

Price Differences Between Automatic and Semi-Automatic Packaging Machines

The gap between automatic and semi-automatic machines is about more than just price — it’s about what you need from your production line.

Automatic machines handle everything from product feeding to sealing, labeling, and sometimes even boxing. They maximize throughput and minimize labor but require a bigger upfront investment.

Semi-automatic machines still need some operator involvement — for example, loading products or starting cycles — but they’re more affordable and easier to maintain. They can be ideal for smaller-scale operations, seasonal production, or businesses testing new product lines.

Return on Investment (ROI) and Its Relationship with Packaging Machine Prices

One of the smartest ways to assess a machine’s price is to look at how quickly it will pay for itself.

High-performance machines can shorten ROI time by increasing output, reducing waste, and cutting labor costs. In many cases, companies recover their investment in less than a year — especially in high-volume or high-margin industries.

When calculating ROI, remember to factor in savings on repairs, lower downtime, and any boost in sales from improved packaging quality.

Best Investment Opportunities for Packaging Machines in 2025

This year brings plenty of opportunity for companies looking to upgrade or expand.

Domestic manufacturing is producing high-quality machines at prices that can rival imports, giving buyers more choice without sacrificing quality.

Flexible financing options — including leasing and staged payments — are making it easier for businesses to invest in the right equipment without tying up too much capital.

And multi-format machines capable of switching between packaging styles are gaining popularity. These future-proof systems make it easier to adapt to changing customer demands and market trends.

Making the right choice in 2025 isn’t just about today’s needs — it’s about finding a machine that will serve you well for years to come, keeping your production efficient, your packaging competitive, and your costs under control.