Packaging Machine Models

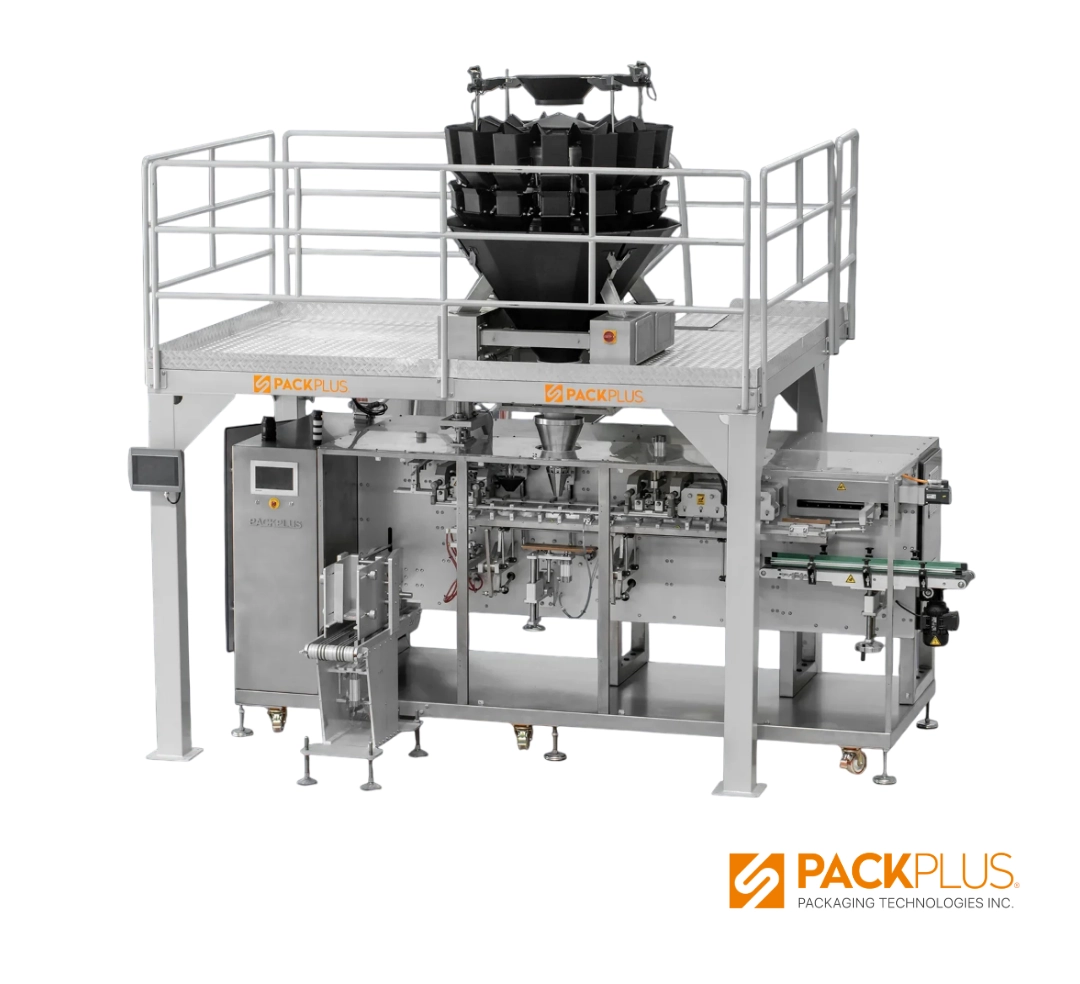

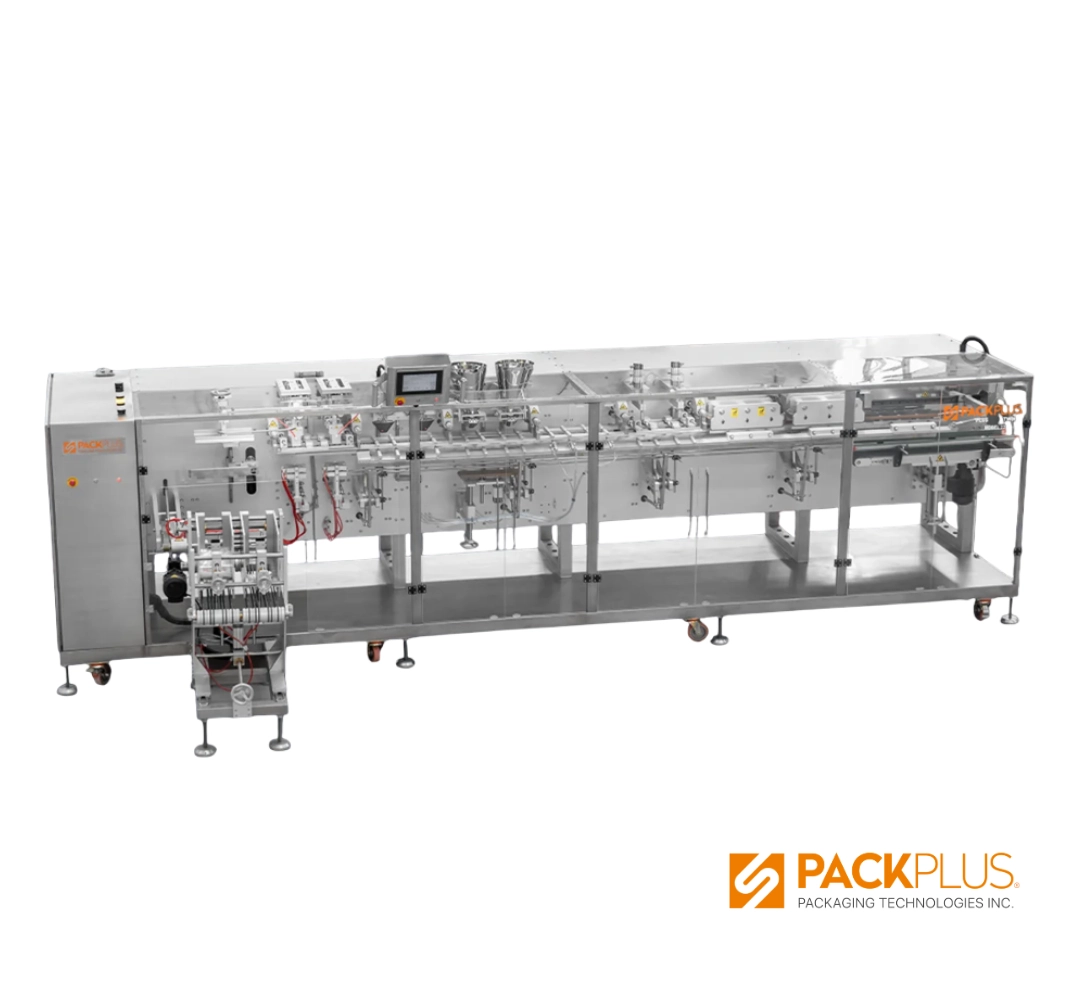

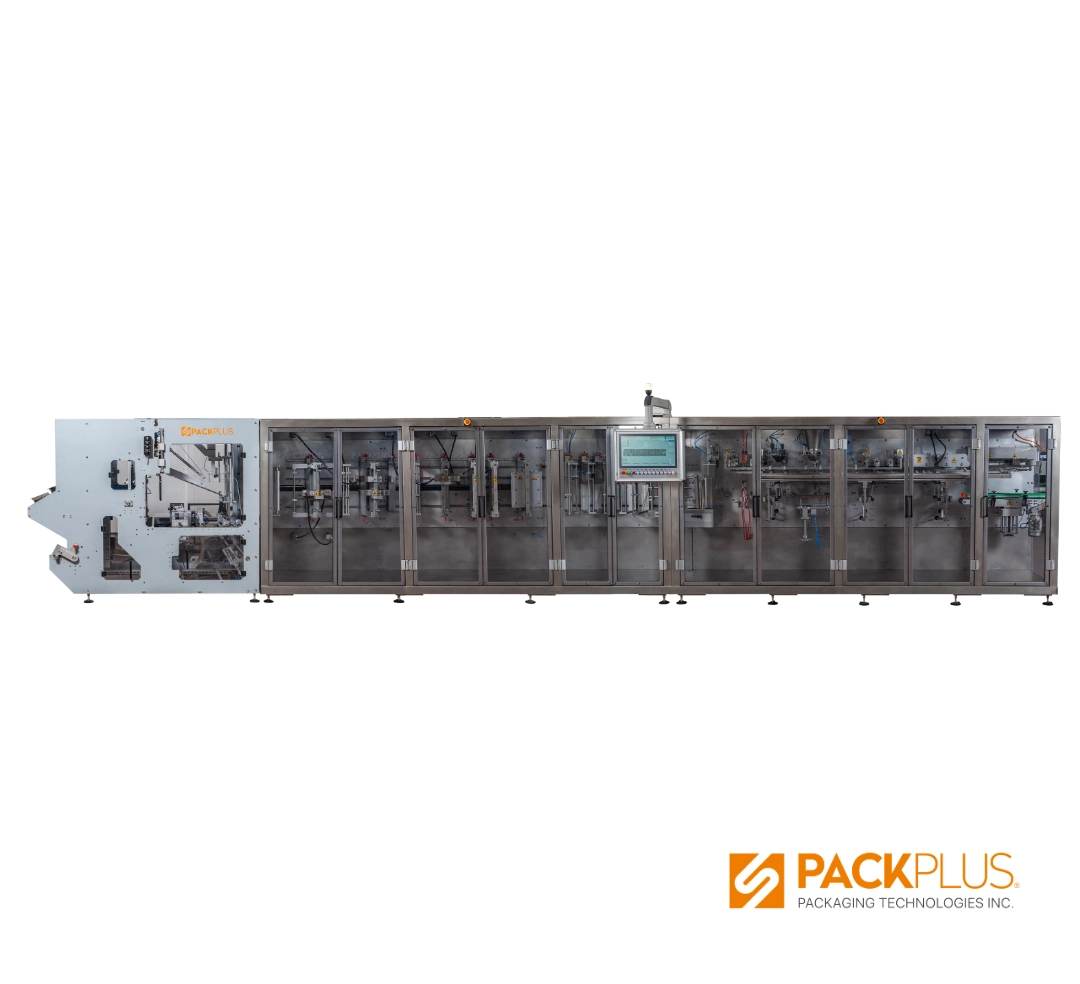

– Doypack Packaging Machines –

– Doypack Machines From Roll-

– Vertical Packaging Machines –

High Performance Packaging Machines

Push your production capabilities further with Packplus high-performance packaging machines. Built for speed, accuracy, and long-term reliability, our systems are designed to meet the demands of high-volume manufacturers across industries. Whether you’re packaging food, chemicals, agricultural products, or personal care items, our machines deliver consistent output with minimal downtime. Robust engineering meets cutting-edge control technology—ready to scale with your business.

Products Packaged with Automatic Packaging Machines

Our automatic packaging machines are designed to adapt to a wide variety of product types and industries. From granulated coffee and detergent capsules to seeds, dried fruits, nuts, or even small metal parts—each product has a tailored filling system, speed configuration, and packaging format. Whether it’s doypack, pillow bags, or gusseted pouches, our machines operate in full compliance with food safety and industrial hygiene standards. Whatever you’re packaging, Packplus delivers smart and flexible solutions tailored to your production needs.

Smart Automation Packaging Machine Solutions

Packplus smart automation systems don’t just speed up your production—they make it safer, more efficient, and fully under control. With touchscreen panels, automatic error alerts, remote monitoring, and production reporting, our machines reduce operator dependency and minimize human error. Thanks to fully synchronized software that works in harmony with the filling system, you get consistent, high-precision packaging with every cycle. All this technology comes with a modern, user-friendly interface—designed to simplify operations while maximizing productivity.

Working Principle of a Packaging Machine

For Everything You Wonder About Packaging Machines

Get Offer / Contact Us

FAQ – Packaging Machine

What Is a Packaging Machine?

A packaging machine is an industrial system designed to automatically fill, form, and seal products into ready-to-ship units. These machines are used to package a wide range of materials — from powders and liquids to granules and solid items — in various formats such as pouches, bags, or boxes. Packaging machines reduce human error, speed up production, and ensure product consistency across all units.

How Do Packaging Machines Work?

Packaging machines operate through an automated process that typically involves dosing the product, shaping the packaging material, filling it, sealing it, and preparing it for labeling or shipping. Advanced machines are equipped with sensors, servo motors, and PLC-based controls that monitor and adjust the process in real time, ensuring accuracy and efficiency throughout every cycle.

How Much Do Packaging Machines Cost?

The cost of a packaging machine depends on several factors, including the machine type, automation level, packaging speed, supported formats, and custom features like metal detection or gas flushing. Entry-level semi-automatic machines may start at a lower price point, while high-speed, fully automatic systems with integrated quality control can represent a more significant investment. However, most machines offer a fast return on investment through labor savings and increased output.

How Do I Choose a Packing Machine?

Choosing the right packaging machine starts with understanding your product characteristics (powder, liquid, granule, etc.), production volume, and packaging format. It’s also important to consider your long-term scalability, energy efficiency needs, and the level of automation your team can handle. At Packplus, we offer tailored consultations to help you identify the best-fit model for your operation.

Which Industries Use Packaging Machines?

Packaging machines are used across a wide range of industries including food and beverage, agriculture, pet food, pharmaceuticals, cosmetics, chemicals, and home care. Whether you’re packaging ground coffee, seeds, snacks, detergents, or personal care products, there is a packaging solution designed to suit the unique requirements of your sector.

What Are the Advantages of Using a Packaging Machine?

Using a packaging machine enhances speed, consistency, and hygiene in the production process. It reduces manual labor costs, minimizes packaging waste, and increases overall throughput. Automated systems also help companies maintain uniform product appearance and meet strict industry standards for packaging safety and quality.

Are Packaging Solutions Compatible with All Production Lines?

Most modern packaging machines can be customized or integrated into existing production lines. At Packplus, we offer modular designs and flexible configurations that allow seamless integration with upstream and downstream systems such as filling stations, conveyors, checkweighers, and palletizers. This ensures a fully synchronized and efficient production flow.

Can the Machine Handle Multiple Product Formats?

Yes, many of our machines are designed to accommodate multiple product types and packaging sizes. With interchangeable filling heads, adjustable format parts, and programmable settings, a single machine can be adapted to switch between different product lines — reducing changeover time and maximizing line flexibility.

What Types of Packaging Formats Are Supported?

Our machines support a wide variety of packaging styles including doypacks, pillow bags, stick packs, gusseted pouches, quad-seal bags, and more. We also work with different materials such as laminated films, recyclable plastics, kraft paper, and aluminum barrier films. The format you choose can be optimized based on your product, branding, and shelf-life requirements.

How Is the Machine Installed and Operated?

After delivery, our technical team handles full installation on-site, including system calibration and integration with your existing equipment. We provide in-depth operator training, covering machine use, maintenance, and troubleshooting. Our machines feature intuitive touchscreen interfaces, making daily operation simple and efficient even for first-time users.

Do You Offer After-Sales Support Services?

Absolutely. Packplus provides comprehensive after-sales support including spare parts supply, remote diagnostics, maintenance plans, and on-site service when required. Our team is always available to help you resolve issues quickly, ensure smooth operation, and extend the lifecycle of your machine.