Filling Units

Supplementary Products

Smart and Technological Solutions Compatible with Our Machines, Complementing Your Production

FILLING

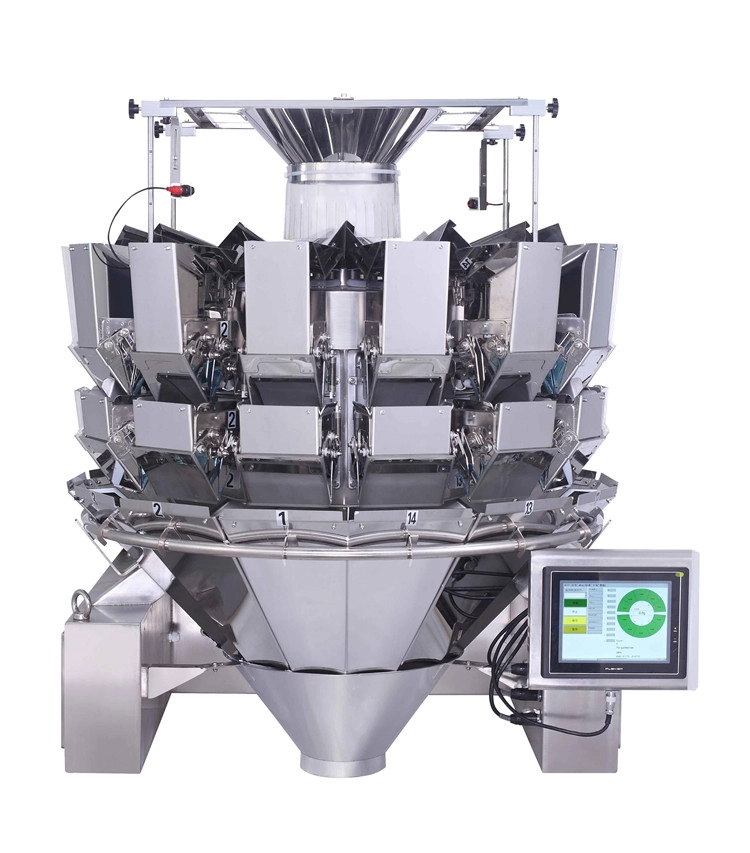

High Efficiency and Precise Filling Systems/Dosing Units

Definition and Use of Filling Systems/Supplementary Products

Filling systems and supplementary products play a crucial role in modern packaging processes, ensuring precision, efficiency, and product consistency. Filling systems are designed to measure and dispense exact amounts of liquids, powders, granules, or other materials into containers, providing reliable and uniform output. Supplementary products, on the other hand, include a variety of tools and equipment that support the filling process, such as capping machines, conveyors, and labeling systems. Together, these systems streamline production, reduce waste, and improve overall operational efficiency, making them essential for businesses across industries like food and beverage, pharmaceuticals, cosmetics, and more.

SENSIBILITY

Supplementary Products for Perfect and Fast Packaging Processes

Filling Systems / Supplementary Products for Every Need with Packplus

For Everything You Wonder About Filling Systems/Supplementary Products

Get Offer / Contact Us

Smart Solutions for Maximum Efficiency in the Packaging Process

High Speed

Touch Control

CE Standard

Optimized Production with Filling Systems and Supplementary Products

Streamline your operations and achieve optimized production with Packplus’ cutting-edge filling systems and supplementary products. Designed to minimize errors and boost efficiency, our solutions cater to businesses looking to scale up without compromising quality. From precise dosing mechanisms to robust supplementary tools, our equipment is built to handle even the most demanding production lines. Let Packplus help you reduce bottlenecks, improve product consistency, and enhance the overall performance of your packaging process, ensuring your business stays ahead in a competitive market.

FAQ – Filling Systems/Supplementary Products

What are filling systems, and how do they work?

Filling systems are specialized machines designed to dispense accurate quantities of liquids, powders, or granules into containers like bottles, jars, or bags. These systems use advanced mechanisms such as volumetric, gravimetric, or flow-based technologies to ensure precision, speed, and consistency, making them essential for industries like food and beverage, cosmetics, and pharmaceuticals.

What are supplementary products in the packaging process?

Does Packplus offer customized filling systems and supplementary products?

Yes, we provide tailored solutions to meet your specific production needs. Whether you require a compact filling system for limited space or a fully automated setup for large-scale operations, we work closely with you to design and deliver equipment that integrates seamlessly into your existing workflow.

What industries benefit from filling systems and supplementary products?

Filling systems and supplementary products are versatile and widely used across industries like food and beverage, pharmaceuticals, cosmetics, chemicals, and household products. Any business that requires precise, efficient, and hygienic packaging can benefit from these solutions.

How do Packplus filling systems improve production efficiency?

Our filling systems are designed for precision and speed, reducing material waste and minimizing downtime. When paired with supplementary products like automated conveyors and sealing machines, your packaging process becomes even more streamlined and cost-effective, boosting overall productivity.

Are Packplus filling systems easy to use and maintain?

Absolutely! Our machines are built with user-friendly interfaces and intuitive controls, making them easy to operate. We also prioritize low-maintenance designs and provide comprehensive technical support and training to ensure your team can keep operations running smoothly.

Do you provide after-sales support for your filling systems and supplementary products?

Yes, Packplus offers exceptional after-sales support, including installation assistance, routine maintenance, spare parts, and technical troubleshooting. Our goal is to ensure your equipment performs reliably and efficiently throughout its lifespan.

Can I integrate Packplus filling systems into my existing production line?

Definitely! Our systems and supplementary products are designed for seamless integration with your existing production line. Our experts will assess your setup and recommend the most suitable equipment to optimize your workflow.

How do I choose the right filling system or supplementary product for my business?

Choosing the right equipment depends on your production volume, product type, container specifications, and budget. Our team of experts will guide you through the selection process, ensuring you invest in solutions that perfectly match your needs.

Are Packplus filling systems environmentally friendly?

Yes, our systems are designed to minimize waste, reduce energy consumption, and maximize efficiency, contributing to sustainable production practices. We’re committed to helping businesses achieve eco-friendly operations while maintaining high-quality standards.