Detergent Packaging Machine – Doypack

In an increasingly competitive global market, manufacturers of cleaning and hygiene products must continually adapt to consumer demand for efficiency, convenience, and sustainability. One of the most critical components in this sector involves how products are packaged and presented. This is especially true in the realm of detergents—whether in powder, liquid, or capsule form. Choosing the right packaging solution can mean the difference between a thriving brand and one that struggles to compete.

This article will delve into the world of Detergent Packaging Machine solutions, focusing on the advantages of Doypack packaging, the special considerations for capsule products, and the factors that influence machine pricing. We will also explore how manufacturers can ensure optimal quality and efficiency in the packaging process. Finally, we’ll highlight Packplus’s expertise in producing machines tailored to meet the demands of modern detergent packaging lines.

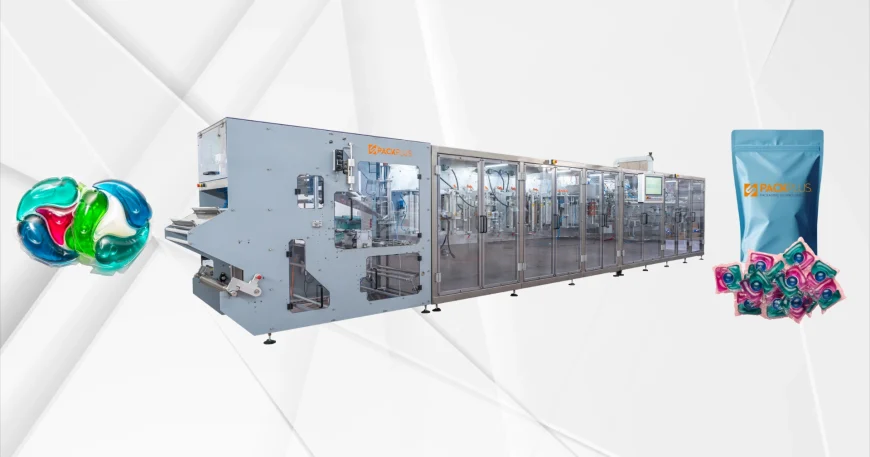

Full Automatic High Speed HFFS(Horizontal Form Fill Seal) Packaging Machine

What Is a Detergent Packaging Machine and How Does It Work?

A Detergent Packaging Machine is specialized industrial equipment designed to package detergents in various forms—powder, liquid, capsule, or pod—into pouches, bottles, sachets, or other containers. The machine’s primary goal is to ensure that each package is accurately filled, hermetically sealed, and protected from external factors such as moisture, light, and contaminants. This level of precision is vital, as detergents can lose efficacy or become clumpy if exposed to humidity or temperature fluctuations. How It Works:

- Product Feeding: Detergent is fed into the machine via hoppers, conveyor belts, or liquid pumps, depending on the product form.

- Measuring & Filling: The machine uses advanced sensors and scales to measure the correct dosage. This ensures consistent product amounts in each pouch or container.

- Pouch/Forming & Sealing: Once the product is dispensed, the package is formed (if the film is on a roll) or simply sealed (if a pre-formed pouch is used). Heat sealing, ultrasonic sealing, or other methods might be employed, depending on the material.

- Final Checks & Discharge: The finished package may pass through a checkweigher or inspection station to confirm it meets weight and quality standards. The completed pouches or containers are then discharged, ready for boxing and distribution.

Modern Detergent Packaging Machine designs place a high emphasis on hygiene, speed, and automation. State-of-the-art models often include touchscreen interfaces, remote monitoring, and easy-to-clean surfaces. This not only boosts output but also maintains consistent quality across thousands, or even millions, of individual packages.

Detergent Packaging Lines with Doypack Packaging Machine Advantage

Doypack stands out in the packaging world for its flexible, upright pouch design. Originally used for items like snacks and beverages, Doypack has also proven ideal for detergents. Manufacturers have started adopting this style to tap into consumer preferences for easy storage, lightweight packaging, and resealability.

Key Advantages of Doypack Machines in Detergent Packaging:

- Reduced Material Waste: Doypack pouches often use less material compared to rigid containers, minimizing environmental impact.

- Shelf Appeal: The upright pouch design helps products stand out on the shelf, offering more branding space.

- Portability & Convenience: Resealable zippers allow consumers to maintain product freshness and avoid spills. This is particularly useful for powdered detergents.

- Enhanced Protection: Multi-layer films used in Doypack packaging shield detergents from moisture and UV light, preserving their cleaning power.

- High-Speed Automation: Modern Doypack-compatible Detergent Packaging Machine models can handle large output volumes, making them suitable for both local and global markets.

Because of their versatility, Doypack machines also provide manufacturers with the ability to package a range of detergent variations, from concentrated powders to liquid detergents. With the proper film selection, a single production line can adapt to multiple product types, which is especially helpful in markets that demand frequent product innovation or seasonal product variations.

Packaging Considerations for Capsule Detergents

Capsule detergents—often referred to as pods—have surged in popularity due to their convenient, pre-measured format. While this form offers major advantages for consumers, it poses unique challenges for packaging. Since each capsule is coated in a water-soluble film, even minor humidity can compromise product integrity. Critical Factors for Capsule Packaging:

- Moisture Control: Capsules must be kept in an environment with strictly controlled humidity. A specialized Detergent Packaging Machine for capsule products typically includes dehumidifiers or enclosures to limit moisture exposure.

- Gentle Product Handling: Capsules can easily rupture if excessive pressure is applied. Machines designed for capsules use gentle handling systems, often with soft conveyor surfaces or customized feeding units.

- Accurate Pouch Sealing: Given their susceptibility to damage, capsules require packaging materials that offer robust sealing without applying too much heat or pressure on the capsules themselves. High-barrier films also reduce the risk of moisture seeping in.

- Safety Measures: Capsule detergents can pose a risk if accidentally ingested by children, so the packaging must adhere to local regulations, often including child-resistant features or prominent warning labels.

The convenience factor drives the popularity of capsule detergents in markets like North America and Europe. As a result, equipment tailored to these products can help brands stand out in an increasingly crowded market. Investing in a capsule-oriented Detergent Packaging Machine not only ensures top-notch product protection but can also raise brand prestige, since consumers view capsules as a premium option.

Efficient and Suitable for Your Production Line Detergent Packaging Machine

Whether you are running a small detergent business looking to scale or a large multinational aiming to refresh your packaging line, selecting an efficient Detergent Packaging Machine is paramount. But efficiency goes beyond production speed; it includes flexibility, minimal downtime, and operator-friendly functionality. Key Traits of an Efficient Machine:

- Scalability: As demand grows, your machine should be able to handle increased output without requiring a complete systems overhaul.

- Flexible Packaging Formats: Some lines need the ability to switch swiftly between various pouch sizes, from small sample packs to large refill bags.

- User-Friendly Controls: Modern machines typically employ intuitive touchscreen interfaces, reducing the learning curve for new operators and speeding up product changeovers.

- Durability & Maintenance: Regular cleaning is crucial when dealing with chemicals. Machines built with stainless steel frames and easily accessible parts streamline maintenance and reduce contamination risks.

- Integration with Existing Lines: A good machine should integrate seamlessly with upstream and downstream processes, such as mixing, sealing, labeling, and palletizing.

A truly efficient Detergent Packaging Machine will also gather performance data, allowing you to pinpoint bottlenecks or inefficiencies in real time. By tracking metrics like average fill rate, error rates, and downtime, manufacturers can make data-driven adjustments to improve productivity. In a global market, this competitive edge can significantly boost a brand’s standing and profitability.

Detergent Packaging Machine Prices and Cost Analysis

When purchasing a Detergent Packaging Machine, price is often the first consideration. However, the initial price tag is only one part of the overall cost picture. Savvy manufacturers also examine operational expenditures, maintenance requirements, and the potential return on investment (ROI). Factors Affecting Machine Cost:

- Production Capacity: Machines capable of rapid, high-volume output tend to come at a higher price. For businesses planning substantial growth, paying more upfront can save money in the long run.

- Automation Level: Fully automated systems reduce labor costs but usually involve higher initial investments. Yarı-automated or semi-automated machines might be more budget-friendly but require more operator oversight.

- Specialized Features: Capsule packaging often needs humidity controls or gentle feeding mechanisms. Doypack lines might require specific attachments for resealable zippers. Each added feature raises the overall machine cost.

- Material Quality & Compliance: Machines built with corrosion-resistant metals like stainless steel can significantly outlast cheaper alternatives. Likewise, compliance with regulations such as CE or UL standards can influence pricing.

- Maintenance & Spare Parts: Some manufacturers offer bundled service agreements, ensuring expert technicians are readily available. Opting for these can reduce costly downtime if a critical part fails.

Cost vs. Value:

A top-tier Detergent Packaging Machine might appear expensive upfront, but these costs can be offset by faster cycle times, lower wastage, and decreased downtime. Additionally, advanced quality checks can reduce customer complaints and returns. Over a few years, these benefits often outweigh the initial expense. A thorough cost-benefit analysis helps in selecting the right machine based on your production goals and budget constraints.

How to Ensure Quality and Efficiency in Detergent Packaging Process?

Achieving both quality and efficiency in the detergent packaging process demands a balance of proper equipment, consistent training, and rigorous quality control protocols. Below are strategic considerations to keep your operations running smoothly while maintaining product integrity:

- Optimized Workflow: Arrange equipment in a logical sequence, ensuring minimal product transport and reduced wait times. This creates a streamlined system where raw detergents move seamlessly from the feeding station to the final packaging stage.

- Regular Machine Calibration: A Detergent Packaging Machine relies on precise measurement systems to deliver the correct volume or weight. Frequent calibration prevents overfills, underfills, and wastage.

- Quality Assurance Protocols: Install sensors or cameras to detect packaging defects, such as incomplete seals or pouch tears. Automated rejection systems can instantly remove faulty pouches, safeguarding your brand’s reputation.

- Training & Personnel Development: Even the most advanced machine performs better under skilled supervision. Train staff to troubleshoot minor issues, conduct routine maintenance, and recognize early signs of machine fatigue.

- Compliance with Safety Standards: Make sure your packaging line meets regional safety regulations. Proper labeling, child-resistant features, and accurate ingredient disclosures are critical in many countries.

- Continuous Improvement: Gather production data—like throughput, downtime, error rates—and regularly review these metrics. Implementing small, incremental changes can lead to significant efficiency gains over time.

When quality and efficiency are both optimized, manufacturers can reduce product returns, minimize reputational risks, and increase customer satisfaction. This dual focus can be especially powerful in detergents, where consumer loyalty is largely determined by perceived product effectiveness and reliability.

Our Expertise in Detergent Packaging Machine Production as Packplus

At Packplus, we take pride in our comprehensive approach to designing and manufacturing Detergent Packaging Machine solutions. Our portfolio includes fully automated Doypack systems, specialized capsule packaging lines, and hybrid machinery that can handle a range of detergent forms. Whether your target market is the United States, the United Kingdom, or other global regions, our machines meet international standards and can be customized to fulfill local regulatory requirements.

Why Choose Packplus?

- Cutting-Edge Innovation: Our research and development team continuously explores new technologies—from smart sensors to user-friendly interfaces—to keep your production line on the leading edge.

- Robust Construction: Built for longevity, our machines use high-grade materials and undergo stringent testing before leaving the factory. This reduces maintenance needs and maximizes uptime.

- Tailor-Made Solutions: We understand that no two production lines are alike. From capacity modifications to packaging style adjustments, our engineers work with you to create a Detergent Packaging Machine that perfectly aligns with your goals.

- Global Support Network: Whether you need machine installation, operator training, or a spare part in a hurry, our service teams are on hand around the world. Quick and responsive support keeps your operations running.

- Focus on Sustainability: Many of our designs incorporate eco-friendly features, such as low energy consumption and minimal film waste. This aligns with growing consumer demand for sustainable packaging.

Our commitment to continuous improvement and collaboration makes Packplus a trusted partner for both large-scale multinational corporations and local detergent producers looking to broaden their reach. By combining technical expertise with a deep understanding of market trends, we deliver solutions that consistently exceed expectations.

Conclusion

The detergent industry shows no signs of slowing down, given the global demand for products that simplify cleaning tasks and enhance hygiene. Packaging, an essential component of any detergent brand’s success, requires careful consideration of material choice, product handling, machine efficiency, and regulatory compliance. Whether you are drawn to Doypack pouches for their convenience or focusing on capsule detergents for their pre-measured precision, the foundation of your operation will always be a reliable and adaptable Detergent Packaging Machine.

From understanding the fundamentals of how these machines operate to exploring cost and efficiency aspects, a well-informed decision can propel your brand forward in both domestic and international markets. Choosing the right machinery not only optimizes your production line but also safeguards product quality, ultimately strengthening customer trust and brand reputation.

At Packplus, we stand ready to guide you on this journey. With our extensive experience in designing, manufacturing, and supporting Detergent Packaging Machine lines worldwide, we invite you to discover how our solutions can meet and exceed your production requirements. By investing in advanced packaging technology now, you can set a solid foundation for success in an ever-evolving, competitive industry.