Food Packaging Machine Solutions

In today’s fast-paced world, packaging has become an essential factor in the food industry, ensuring products reach consumers safely, hygienically, and attractively. The right packaging solution not only protects the integrity of food products but also boosts their shelf appeal and consumer trust. At Packplus Food Packaging Machinery Manufacturer, we specialize in providing state-of-the-art food packaging machine solutions designed to meet the diverse needs of businesses worldwide. In this comprehensive article, we’ll explore everything you need to know about food packaging machines, their benefits, and how they can significantly enhance your business operations.

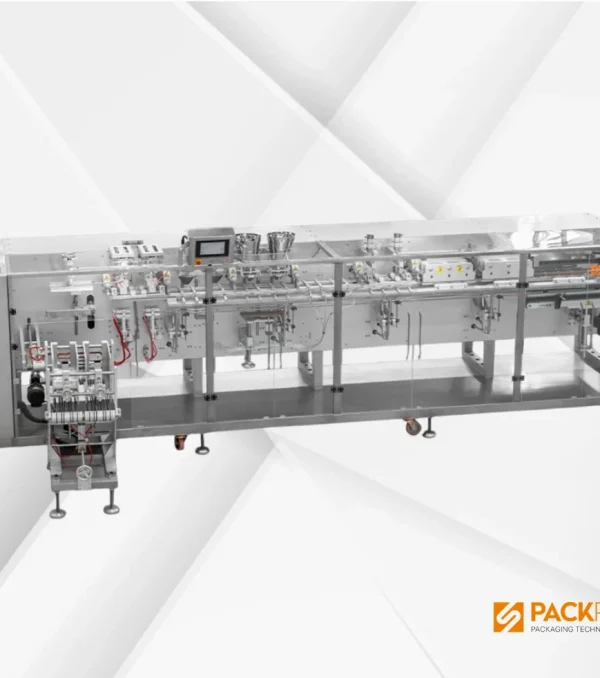

Full Automatic Pre-Made Package Horizontal Packaging Machine

What is a Food Packaging Machine and How Does It Work?

A food packaging machine is a sophisticated piece of equipment designed to automate the packaging process of various food products. These machines ensure food products are efficiently measured, filled, sealed, and packaged, minimizing manual handling and potential contamination. They typically operate through a series of well-coordinated steps—starting with precise weighing or volumetric filling of food items, followed by transferring the products into suitable packaging materials. The final step involves sealing the packages securely, often through heat sealing or ultrasonic methods, ensuring the contents remain fresh and protected during transport and storage.

Advanced food packaging machines, such as those provided by Packplus, incorporate digital controls, sensors, and intuitive user interfaces that allow operators to monitor and adjust machine parameters effortlessly. This technology ensures consistency, accuracy, and efficiency across every production cycle, significantly reducing waste and operational costs.

What Are the Advantages of Using a Food Packaging Machine?

Utilizing a food packaging machine offers numerous advantages. Firstly, automation drastically increases packaging speed, allowing businesses to handle larger volumes of products in significantly less time compared to manual packaging. This heightened productivity helps businesses meet tight deadlines and seasonal spikes in demand without compromising quality. Secondly, consistency and precision are major advantages of these machines. Automated systems provide accurate portioning, reducing product giveaway and ensuring compliance with labeling and weight regulations. This reliability translates to consumer satisfaction and trust.

Additionally, the use of food packaging machines minimizes human contact, thus enhancing food safety and hygiene. With fewer opportunities for contamination, businesses can confidently meet stringent hygiene standards required by local and international regulations. Furthermore, automated packaging machines contribute to reduced labor costs and lower instances of work-related injuries caused by repetitive tasks.

How to Choose the Right Food Packaging Machine?

Selecting the right food packaging machine involves evaluating several critical factors. Firstly, consider the type of food product your business handles. Different machines cater specifically to solid, liquid, powdered, or granular products. Identifying your product type helps determine the most suitable filling and sealing mechanisms.

Next, assess your required production capacity. Smaller businesses might benefit from compact, semi-automatic machines, while large-scale producers will require high-speed, fully automatic machines capable of handling substantial production volumes.

Packaging material compatibility is another vital factor. Ensure the chosen machine is compatible with your packaging materials, such as polyethylene, paper-based materials, or laminated films. Compatibility guarantees optimal sealing and durability of the packaged products.

Lastly, evaluate ease of use, maintenance requirements, and availability of after-sales support and spare parts. Machines designed with user-friendly interfaces, accessible maintenance procedures, and reliable support services ensure smoother operations and minimal downtime.

Increase Your Business’s Production Capacity with a Food Packaging Machine

Save Time and Labor with an Automatic Food Packaging Machine

Automation in packaging processes directly translates into substantial time and labor savings. Automatic food packaging machines handle repetitive tasks like weighing, filling, and sealing, freeing human resources for more strategic roles within your business. This optimization not only reduces operational costs but also improves employee satisfaction by minimizing monotonous, physically demanding tasks.

Moreover, automated machines maintain consistent packaging rates throughout production shifts, unaffected by fatigue or human error, resulting in increased operational efficiency and reduced downtime. Businesses can redeploy labor resources to focus on quality control, product development, and customer engagement, driving overall business growth and competitiveness.

Food Packaging Machine Pricing and Return on Investment

Investing in a food packaging machine requires initial capital, yet the return on investment (ROI) is highly favorable when considering long-term operational savings and productivity gains. Prices vary based on automation levels, features, and capacity requirements. However, businesses quickly recover these initial investments through reduced labor costs, minimized packaging errors, and enhanced production efficiency.

Evaluating ROI involves calculating savings on labor, reduced waste due to precision packaging, and increased output allowing more products to reach market faster. Packplus’s team of experts can guide businesses in selecting the most cost-effective solutions tailored to their specific production needs, ensuring optimal ROI.

Food Packaging Machines for Industrial and Small-Scale Production

Packplus provides versatile food packaging machines suitable for various business scales—from small artisanal producers to large industrial manufacturers. Small-scale businesses benefit from semi-automatic machines offering affordability, compact size, and ease of operation. These machines enable artisan producers to maintain professional packaging standards without significant capital investment.

Conversely, industrial-scale operations benefit from high-capacity automatic packaging machines designed for continuous operation, handling large production volumes with minimal downtime. Such machines feature advanced capabilities, including high-speed processing, automatic error detection, and compatibility with integrated packaging lines, ensuring seamless operation in high-demand environments.

Hygiene and Quality Standards in Packaging

Maintaining hygiene and quality standards is paramount in food packaging. Packplus food packaging machines are meticulously designed to meet international food safety standards such as FDA, HACCP, and ISO regulations. These machines feature stainless steel construction, smooth surfaces, and easy-to-clean components, minimizing contamination risks and ensuring compliance with stringent hygiene requirements.

Additionally, automated machines enhance traceability by incorporating batch coding, best-before dating, and other labeling options directly on the packages. Such traceability aids regulatory compliance, product recalls, and quality audits, providing peace of mind to both producers and consumers.

By investing in Packplus’s food packaging machine solutions, businesses ensure their products meet the highest quality and safety standards, boosting consumer confidence and brand reputation globally. Contact Packplus today and discover how our innovative packaging solutions can drive your business forward.

Conclusion

Selecting the right food packaging machine does much more than simply accelerate your production line—it also enhances your brand’s credibility, expands your export potential, and significantly boosts profitability. By collaborating with Packplus’s team of experts, you can build a flexible, future-proof, and sustainable packaging infrastructure tailored to your current and upcoming needs. Take the first step toward a packaging system that promises high return on investment, impeccable hygiene standards, and readiness for global competition, ensuring your products earn their rightful place on shelves worldwide.